As an engineer of a road construction company, I had managed many foundations and road machines installation. So, i want to share some experience of foundation making and installation for asphalt mixing plant in the end user engineer’s view.

Move out the first step is very important. Even through that I have the experience of the related work, but to be honest, it is my first time to make the foundation and assembly the asphalt mixing plant machine and what’s more, it is from China. I am worried about the foundation and layout drawing, if it was in Chinese, that would be a problem for me. Anyway, I must get the foundation and layout drawing firstly.

Fortunately, it was in English when I got the asphalt plant referred drawings from the Chinese manufacturer. I studied the drawings and printed them, and took the level and long tape measure and other instruments to the yard where the asphalt plant will be installed. Firstly to check the soil geological condition, then to find out the mixing tower center, make a clearly mark according to asphalt plant foundation layout, and check where is for the finished asphalt transfer truck lane come and go, and where for aggregates storage,and also where is the location of the aggregate loading direction, also where is the bitumen tanks and control room and dust collection system. After conformed the layout of the plant main parts, then I arranged the labors to make line with white color based on the mixing tower center point to each main parts of the asphalt mixing plant. Next step will make the foundation according to the drawings and each main parts load, make different depth and compacted the soil, and prepare the embedded parts such as re-bar and steel plates showing on the foundation drawing. After these work finished, then will fill with the C20 (or above like C25,C30 accordingly )concrete , after days of maintenance and drying, then we can start the installation work.

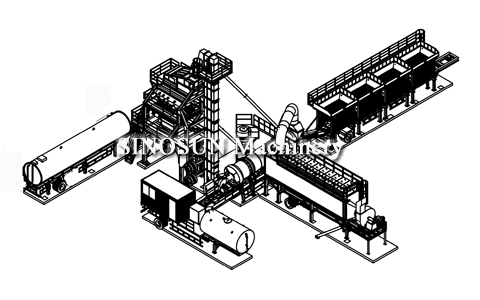

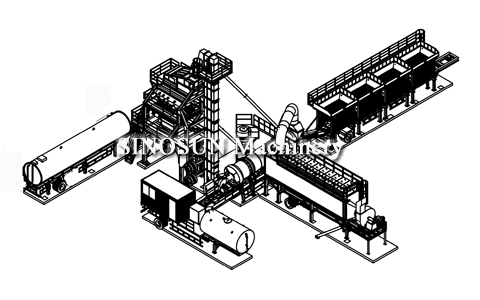

For the installation of the asphalt plant, we had got the assembly drawing and 3D pictures and videos of other similar asphalt plant installation from the manufacturer before their engineers come to the site. And we can do some small parts assembly firstly to save time and cost. After the Chinese asphalt plant engineers come here, then we will work together, and I will ask them to provide a tools list and trucks which will be needed, and how many labors will need for installation the plant. And make an asphalt plant installation plan and schedule. And they told me what capacity and kinds of the crane and loader will be needed, and the sizes of the wrenches, screw drivers, cutting machine, welding machine and other tools and materials.

Then we together to check the foundation, use the level to check each main parts foundation, to see whether we need to add some small pieces steel plate before we put the asphalt plant main parts one the foundation base. After confirm the foundation is ok, then I will follow the Chinese engineer instructions, to find out each main parts of the plant, to move them near each foundation and then to assembly each main parts.

Firstly, we make the mixing tower assembly, because all the other part’s position all is base on it. So we need firstly to finish the mixing tower. After the asphalt mixing tower stand up, we will check if it is in the center of the foundation, and check the balance of each support legs.

The second main part is the hot stone elevator, before we make it up, we will assembly each section firstly, and there will be sealant between each surface of these sections. The elevator will be installed beside the mixing tower, on the top of the elevator and the mixing tower and middle section of the elevator, there will be fixing bolts and nuts( or screw bar). and after the elevator is up, we will check if it is in the middle line of the foundation base, also will check if it is vertically.

The third main parts is the drum dryer and burner assembly. After the stone elevator is fixed, then the drum dryer and burner assembly can be placed near it according to the asphalt plant assembly drawing.and the drum dryer discharging port connected to the elevator receiving hopper.

The fourth main parts is cold aggregate feeding system, it includes the cold feeding bins, and belt conveyors. Before we place the cold bins on the foundation, we have already installed this system main parts, we need make the cold bins and the belt conveyor in one middle line with the drum dryer system, and keep a certain distance and height between the belt conveyor and the drum dryer end part.

The fifth main parts is the bag house dust collecting system, it includes, the bag house, and some screw conveyors and the wind pipe lines, when place this system on the foundation, we need to consider its distance to the drum dryer and the mixing tower, because there are some pipes will be connected to them from the bag house.

The sixth main parts installation will be the bitumen storage and heating system, it normally includes the asphalt tanks, thermal oil heating system(thermal oil boiler), and these parts location will be consider the bitumen circulation pump position, then place the asphalt tank one by one(if you have more than one tanks), and each tanks should make sure the asphalt pipes and thermal oil pipes can connected compacted, make sure no leakage.

The seventh parts will be the filler storage and supplying system, this system includes the filler silo and filler screw conveyors, and filler weighing system.It is designed near the mixing tower and the drum dryer, because the filler silo is very high, we must make sure its foundation is strong, and after stand up the filler silo and confirm its position, we asked the labor to welding the filler silo bottom parts to the steel plate which is embedded on the foundation.

The last main parts are the control room and diesel oil tank, when place the control room, we need to consider the foundation,the cables and wires layout, and also where the operator is easy to operate and can observe the finished asphalt discharge and the asphalt transfer truck activity.

The above is the general configuration of an asphalt plant foundation making and installation, if you asked different configuration of the asphalt plant, you can ask the Chinese manufacturer provide you other support, SINOSUN are online and friendly all the time to provide you the service.